FOOD

Food waste is a thing of the past

Food spoilage: the biggest nightmare of every professional in the food industry. With SenseAnywhere’s AiroSensors, this scenario is a thing of the past. Thanks to this smart measurement solution, you improve food safety, and avoid penalties, damage to your image and the financial consequences of a recall. How? It’s simple: with automated temperature monitoring during transport, processing and storage.

“Fantastic Product, very efficient. If an issue occurs an email and/or text message comes straight through to make you aware. Ensuring that the business can continue and correct the issue if something is wrong. Would highly recommend this equipment to anyone”.

Prevent risks

Are you still registering the temperature in refrigeration units manually? In that case, you’re running the risk of temperature fluctuations. This can result in administrative inefficiencies, food poisoning, food waste, sanctions and, of course, damage to your image. With SenseAnywhere’s AiroSensors, you eliminate those risks. How? It’s simple:

24/7

Place the SenseAnywhere data loggers near the food. Track the goods 24/7 via the SenseAnywhere portal. View data reports with charts and spreadsheets for detailed analysis. And receive real-time alerts by email or SMS when the temperature of a cooling unit goes outside a set range. The data is automatically sent to our secure Cloud and system backups.

Certifications

SenseAnywhere has a robust, systematic, and risk-based approach for Information Security, SenseAnywhere meets the requirements for a Quality Management System and Environmental Management System and our systems enable you to set up and implement a GxP compliant temperature monitoring solution.

5 advantages

- Efficient and simple

- Prevent food waste

- Comply with legal requirements

- Save time and money

- Monitor 24/7

From restaurant

to supermarket

Use our data loggers for refrigeration systems, in production areas and restaurants, but also in processing and cooking environments, storage and distribution facilities, cold chains, retail, catering and supermarkets.

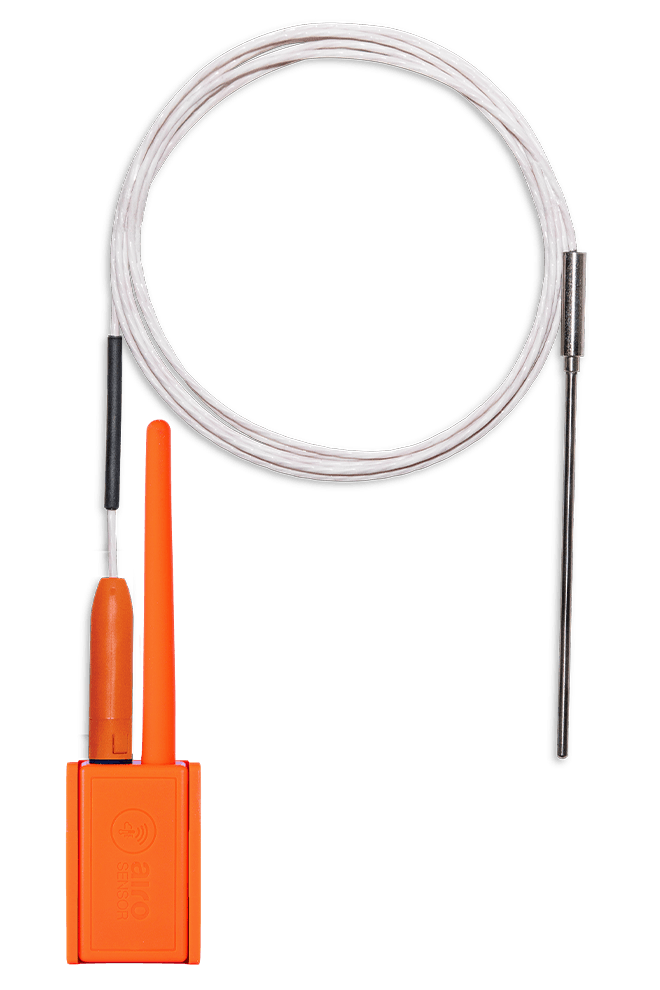

AiroSensor

- Monitor temperatures from -40°C to +70°C

- Highly accurate measurements (± 0.1°C)

- 10-year battery life – 1 million measurements

- Humidity range: 1 – 95 % RH, non-condensing

- The AiroSensor 20-20-43 can be easily

connected to various Modules

AiroSensor

with External Modules

- Real-time digital measurements with

alarm functions -

All measured values in one system

- Monitor temperatures from -200°C

to +200°C - Modules to connect your own 4-wire

Pt100, industry standard analogue

sensors that output 4-20mA or 0-10V

Find a reseller within our global network